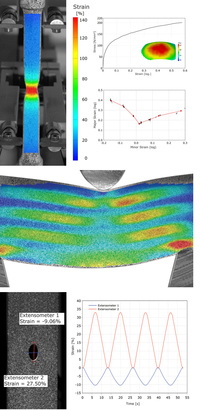

ARAMIS helps to better understand material and component behavior and is  ideally suited to monitor experiments with high temporal and local resolution.

ideally suited to monitor experiments with high temporal and local resolution.

ARAMIS is a non-contact and material independent measuring system providing, for static or dynamically loaded test objects, accurate:

- 3D surface coordinates

- 3D displacements and velocities

- Surface strain values (major and minor strain, thickness reduction)

- Strain rates

ARAMIS is the ideal solution for…

- Determination of material properties (R- and N-values, FLC, Young’s Modulus, etc…)

- Component analysis (crash tests, vibration analysis, durability studies, etc…)

- Verification of Finite Element Analysis

ARAMIS is the unique solution delivering complete 3D surface, displacement and strain results where a large number of traditional measuring devices are required (strain gauges, LVDTs extensometers, …).

The same system setup is used for multiple applications and can be easily integrated in existing testing environments.

CAD data integration

ARAMIS provides an import interface for CAD data which are used for 3D coordinate transformations and 3D shape deviation calculations.

ARAMIS provides an import interface for CAD data which are used for 3D coordinate transformations and 3D shape deviation calculations.

The import interface handles following formats:

- Native: Catia v4/v5, UG, ProE

- General: IGES, STL, VDA, STEP

Real-time data processing

The ARAMIS software provides real-time results for multiple measurement positions from the test objects surface.

These are directly transferred to testing devices, data acquisition units or processing softwares (e.g. LabView, DIAdem, MSExcel, etc.) and are used for:

- Controlling of testing devices

- Long-term tests with smallest storage requirements

- Vibration analysis

- 3D Video Extensometer