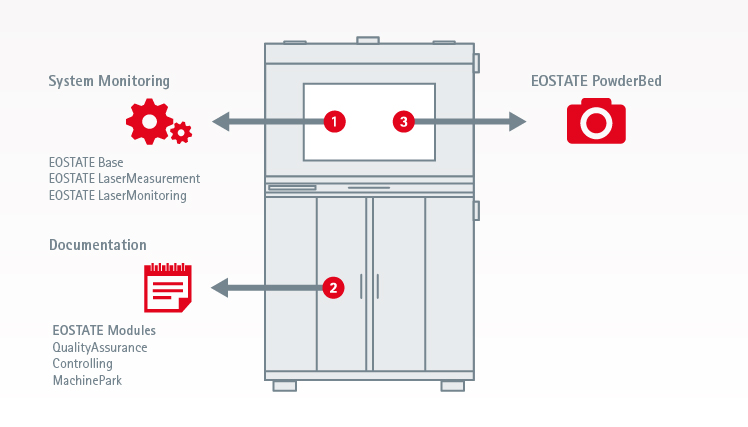

EOS offers its customers a comprehensive range of products for monitoring and recording system status, laser output, and material coating and exposure in the build space. Customers benefit from early error detection and reduced risks and costs in the production process.EOS is constantly striving to improve its quality assurance processes as it consistently pursues its innovation policy. For example, the recently developed EOSTATE PowderBed augments the existing system-monitoring unit and the respective documentation modules with an innovative image-monitoring system.

System monitoring (1 and 2)

EOSTATE Base

- Comprehensive system status monitoring sensors: Laser and scanner status with automated scanner self-calibration, cooling system, electrics complete with power-failure protection, build platform position, dosing system and collector vessels, status of circulating air filter system, process chamber and surrounding atmosphere, temperature of build platform, etc.

EOSTATE LaserMeasurement & EOSTATE LaserMonitoring

- Quality assurance for laser output

EOSTATE documentation modules

- QualityAssurance: for reporting all quality-relevant job and component data and giving statistical presentations of successful build jobs for documentation and tracing purposes

- Controlling: control reports for mapping cost-relevant data and for statistical presentations of successful build jobs for the purpose of cost transparency and analysis and for detecting trends

- MachinePark: reports all data of relevance to the machine park along with statistical presentations of successful build jobs

EOSTATE PowderBed (3)

- Monitors coating and exposure with an integrated camera. Optimised illumination of two build-room images per layer

- Check function by displaying the latest image and scrolling through previous layers of build job on touchscreen

- Option to output as a video clip at the work station computer using the EOSTATE plug-in

Comprehensive quality management

In addition to monitoring products, EOS fulfils its customers stringent quality demands by providing them with a comprehensive quality management system based on 25 years experience in the field of additive production.

EOS offers an expanding range of products in the field of quality management EOS-Services, including maintenance and repair services, training offers, application advice and installation training.

EOS also documents its own standards in the form of certifications of its quality management system and has numerous process and product certificates.

Its product range also includes its material management system IPCM (Integrated Process Chain Management) for optimised material handling.