ATOS ScanBox Series 4

Measurement of Small Complex Components up to 500 mm in Size

Injection and die-cast parts and their tools, molds, stamped and drawn parts often have very complex contours and connection

geometries which have to be checked during the series and batch production ramp-up. The ATOS ScanBox 4105 is an efficient

3D measuring machine for these applications.

Optimized kinematics

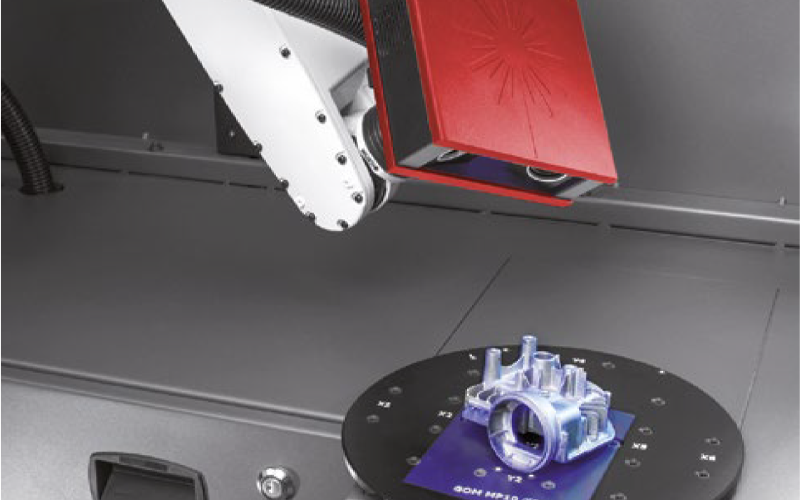

The ATOS ScanBox 4105 shares its kinematic concept with the large measuring machines of Series 5 and 6: The ATOS sensor is attached to a robust and fast industrial robot. The components to be measured are positioned on a rotation table to enable the sensor to measure all the areas of the object from above and below with short distances.

This is possible thanks to the very compact dimensions of the ATOS ScanBox. As the entire

kinematics is controlled by a single electronics system, robot and rotation table can move synchronically, and at the same time, potential collisions are monitored.

Plug & Play

The robust machine housing contains all components of the ATOS ScanBox. As a 100 – 240 V power supply is used and the measuring system only weighs approx. 900 kg, it can be used for measuring in almost all premises. Four wheels enable the unproblematic repositioning of the ATOS ScanBox in the factory shop. The sliding door is designed in such a way that it can be loaded with a crane.

High detail image resolution

Small geometries such as locking hooks or catches for injection molded parts are often very important for the function. In the ATOS ScanBox 4105, ATOS sensors with the smallest individual measurement field of 80 x 60 x 60 mm³ can be used. As a result, it is possible to measure details which are only several tenths of a millimeter in size.

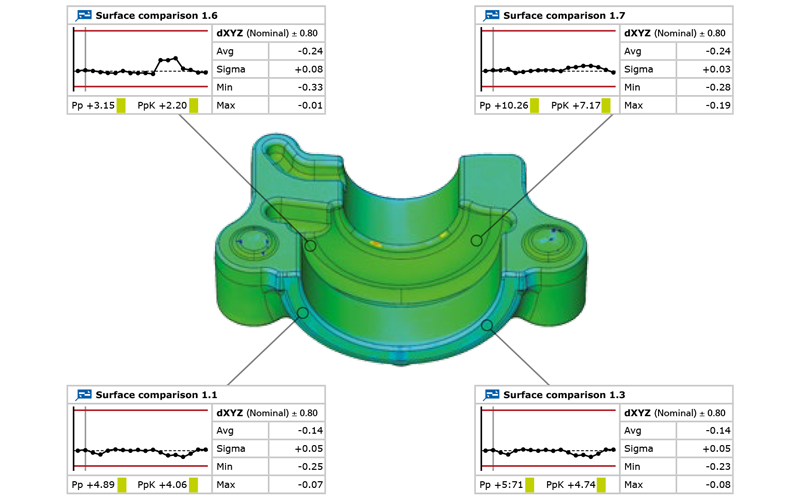

Measuring uncertainty in accordance with VDI 2634

The requirements in terms of measuring uncertainty are high for nearly all the applications of the ATOS ScanBox 4105. The acceptance and monitoring of the system with traceable normals is therefore an integrated function of the software. As the determination of Cg /Cgk and Cp /Cpk values is also implemented as part of the trend analysis, the process and measuring equipment capability can be analyzed with the help of a normal trend project without any additional software or calculations in Excel tables.

Two user interfaces in one single software program

The measuring room provides the specialist with all the functions of the ATOS VMR software for teaching, measuring and evaluating. The Kiosk Interface is activated in production. This way, parts can be measured at the press of a button using existing project templates. The measuring programs and evaluations cannot be changed by the user and the operating system of the integrated computer can no longer be accessed.

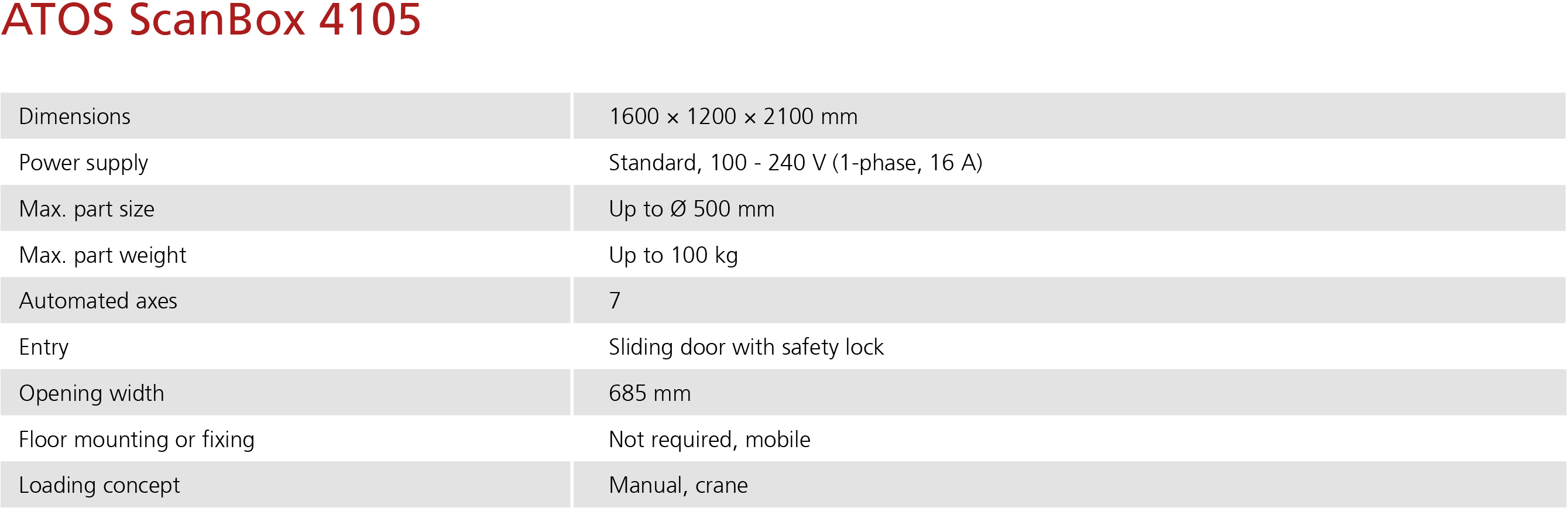

Specification