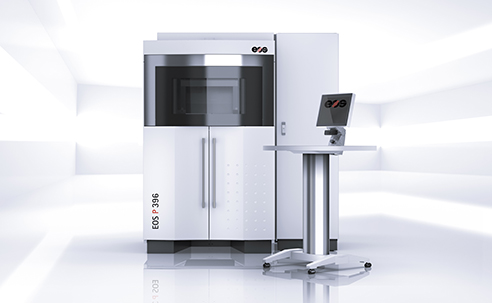

System for Additive Manufacturing of serial parts and functional prototypes from polymer materials. The successor to the EOSINT P 395 offers higher productivity and therefore lower costs per building job. Improved hardware and software ensure greater consistency in part properties.

With total build size of 340 x 340 x 600 mm, the EOS P 396 covers the medium build volume range. This modular

and highly productive system allows the tool-free manufacture of serial components, spare parts, functional prototypes and models directly from CAD data. Compared to its predecessor model, the EOS P 396 consumes for a typical building job (filling ratio 5.8%) about 38% less energy and is up to 32% faster.

Cost-effective manufacturing

- The EOS P 396 processes thermoplastic plastics on an industrial scale. The, to some extent, newly developed software and hardware components make the EOS P 396 on the whole more productive. This cuts both costs per job and component costs.

Reproducible and constant component quality

- The new EOSAME feature adjusts the energy input and thus ensures a homogeneous quality and enhanced mechanical properties of the manufactured parts over the entire building volume.

- Reduced non-productive process times and improved process stability by improved temperature management.

High productivity

- The build progress is on average 15% higher compared to the established EOSINT P 395 (depending on the filler loading and part design). This significantly reduces the component costs.

- Boosted build rate by more powerful 70 W laser.

- Reduced non-productive time by 60 % due to spot pyrometer.

Innovative software

- The latest version 3.7 of the PSW software contains some new features alongside proven functions, features that offer the best possible support during both preparation of the build job and process control during the build progress.

User-friendly

- The machine manufactures very complex plastic parts. But great store is still placed on its easy operation.

Broad material portfolio

- The EOS P 396 can process an extensive portfolio of materials, just like its predecessor.

- With the corresponding ParameterSets, the system produces parts with standardized part property profiles (PPPs).

Mechanical powder handling

- Apart from the familiar IPCM P powder handling solution, the new IPCM P plus is also now available.

Sustainability

- The overall system’s energy consumption could be reduced, thus lowering the operating costs too.

Technical Data

|

EOS P 396 |

|

|

Effective building volume |

340 mm x 340 mm x 600 mm (13.4 x 13.4 x 23,6 in) |

|

Building speed (depending on material) |

up to 48 mm/h (1.9 in/h) |

|

Layer thickness (depending on material) |

0.06 mm (0.00236 in), 0.10 mm (0.00394 in), 0.12 mm (0.00472 in), 0.15 mm (0.00591 in), 0.18 mm (0.00709 in) |

|

Laser type |

CO2, 70 W |

|

Precision optics |

F-Theta-Linse |

|

Scan speed during building |

Up to 6 m/s (19.7 ft/s) |

|

Power supply |

32 A |

|

Leistungsaufnahme |

nominal 10 kW, typical 2.4 kW |

|

Nitrogen generator |

integrated, external connection available |

|

Compressed air supply |

min. 10 m³/h; 5,000 hPa (13.1 yd³/h; 72.5 psi) |

|

Dimensions (W x D x H) |

|

|

System incl. switchgear cabinet |

1,840 mm x 1,175 mm x 2,1 00 mm (72.4 x 46.3 x 82.7 in) |

|

Control terminal |

950 mm x 700 mm x 1,550 mm (37.4 x 27.6 x 6 1 in) |

|

Powder conveying system |

1,480 mm x 1,170 mm x 1,470 mm (58.3 x 46.1 x 57.9 in) |

|

Unpacking station |

1,190 mm x 620 mm x 1,500 mm (46.9 x 24.4 x 59.1 in) |

|

Recommended installation space |

min. 4.3 m x 3.9 m x 3.0 m (169.3 x 153.5 x 118.1 in) |

|

Weight |

approx. 1,060 kg (2,337 lb) |

|

Data preparation |

|

|

Software |

EOS PSW, EOS RP Tools, EOSTATE |

|

CAD interface |

STL |

|

Network |

Ethernet |

|

Certification |

CE, NFPA |