The ARGUS software supports the ARGUS System. The full potential of the available hardware is used to capture and evaluate the measuring area efficiently and with high

accuracy.

The entire measuring, evaluation and documentation process is built on an easy, safe and fast workflow.

Find more information about the ARGUS system for the optimization of sheet metal forming processes and for the verification of numerical forming simulations on the ARGUS metrology system page.

Features

Data Acquisition

- Fully integrated interface for different camera models and different file formats

- Real time display supports the image acquisition

- Automatic multiple-image-mode to cope with difficult lighting conditions

Calculation of surface coordinates and form change

- Automatic calculation of 3D surface coordinates, major and minor strain and thickness reduction

- Thickness reduction and deformation can be calculated in the center line of the sheet

- Calculation of the stress values based upon Flow Curve

- Import of CAD, deviation of CAD to measurement data

- Multi-stage measurements

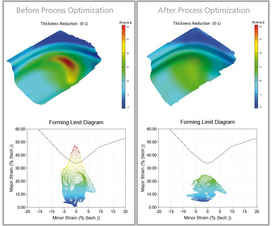

Forming Limit Diagram

- Import functionality for Forming Limit Curves

- Visualization of measuring results in Forming Limit Diagram

- Determination of forming limit curve based upon ISO 12004

- Section based evaluation

- Evaluation of complete measurement series

Primitives

- Primitives (spheres, cylinders, cones, planes, lines …) can be generated from 3D data (certified by PTB and NIST)

- Primitives can be used to adjust the coordinate system of the measurement

Registration

- Registration of the captured data into predefined coordinate systems or into predefined geometrical elements (primitives)

- Display of the calculated values in z-axis for a simple comparison to FEM data

- Registration to CAD or STL

- Combination of multiple measurement areas

Section Data

- Sections can easily be defined, evaluated and the resulting data graphically displayed and exported

- Tools to edit and process the section data

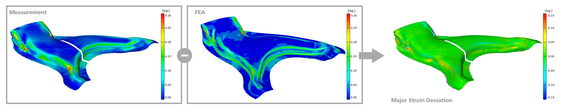

FEA Comparison

- Native import of FEA data-sets (ABAQUS, LS-DYNA, PAM-STAMP, AutoForm and ASCII)

- Full-field comparison of geometry, deformation, displacements and strain values

- Calculation and comparison of major and minor strain, thickness reduction, 3D shape/geometry, X, Y, Z displacements, …

- Export of data-sets and results (surface data, ASCII, sections, diagrams, images, reports, …)

Documentation and Reporting

- Result data overlay on captured images

- Dynamically linked reports for live updating of results

- Variable and adjustable templates for reports

- Extensive reporting capabilities which allow the integration of graphical diagrams, captured images and section diagrams

- Statistic functionality and export functions are available Export of results (ASCII, images, …)

Automation

- Macro functions can be recorded, edited and launched to speed up repetitive steps in the image capturing, post processing, data evaluation and display process

Help

- Automated parameter suggestions for all important functions

- Online help

Software Administration

- All software features completely controllable with seperate administration licence

- Adapt the software to company-specific workflows

- Disable specific system menus and functions

- Integrate user-defined scripts into menus

- Lock system templates so that only company-specific templates are available

- Block creation or editing of templates, scripts or automation protocols