Automated Large Volume 3D Scanning

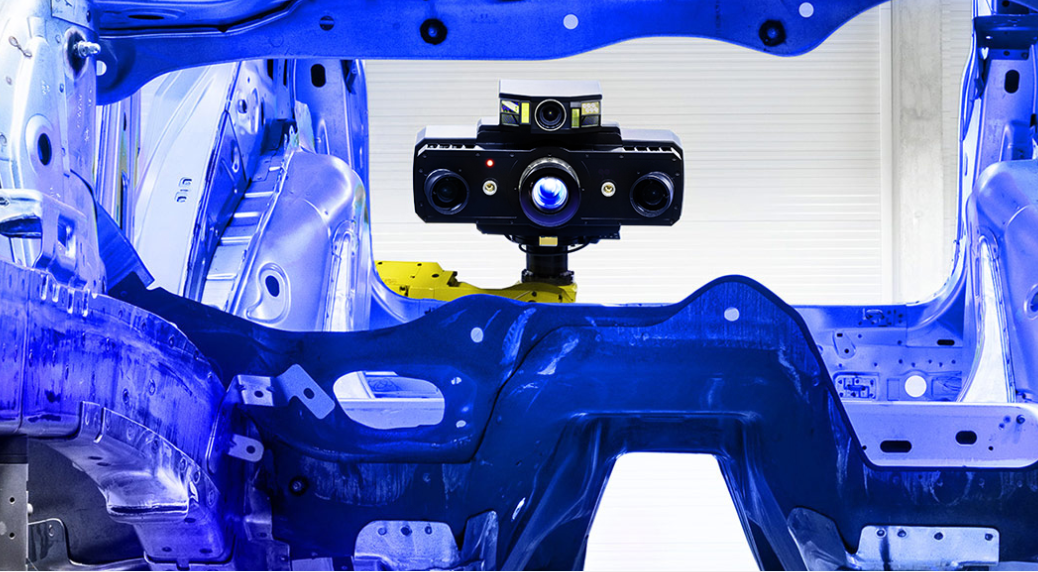

With its powerful light source, ATOS 5X enables the use of large measuring volumes for maximum speed in automated applications. In combination with the ATOS ScanBox series, ATOS 5X is a high-end scanning system for tool, press and body shops.

Features

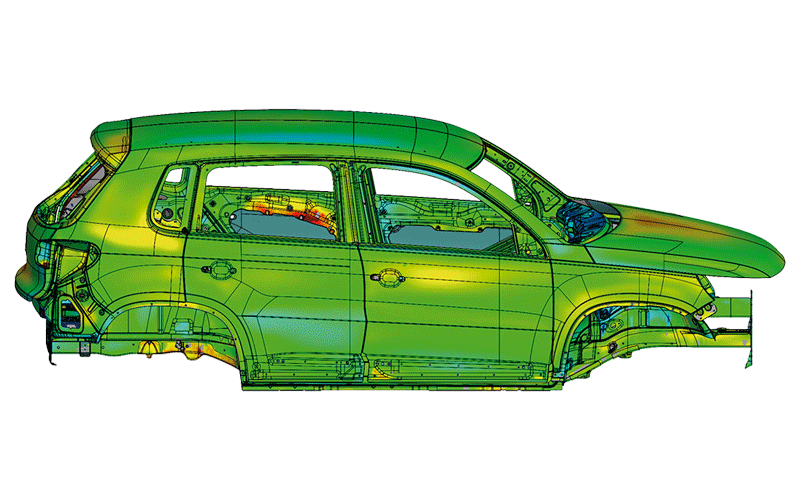

Prior to the actual physical assembly, the measured parts can be virtually aligned. Information on gap and flush or functional dimensions can be evaluated at an early stage. Measuring results deriving from different departments or even from suppliers can be evaluated centrally. This way, a car body can be analyzed irrespectively of Meisterbock or cubing.

Extremely bright laser light source

Resistant to ambient light conditions

Short exposure times

Even for dark and shiny surfaces

High detail resolution

Low noise level and precise coverage of complex geometries

Robust sensor design

High accuracy in rough environments

Interference-free data transfer

Intelligent sensor communication using fiber optics

Process safety

In industrial applications

Speed up your process

The automated measurement of a complete car body both outside and inside typically takes 30 minutes with ATOS 5X – including the precise coverage of complex geometries. The system enables the highest possible throughput, with the main application areas in Meisterbock and Cubing, inspection of complete vehicles and quality control in body manufacturing.

Get the highest data quality

ATOS 5X delivers full-field data for comprehensive process and quality control of hang-on parts, side panels and complete car bodies. The data quality generated by the sensor is particularly evident in the detail sharpness of the 3D models, allowing an advanced inspection of character lines, radii, trimmed edges and hole patterns.