The ATOS Capsule is an optical precision measuring machine (OPMM) for full-field digitizing of contoured part geometries. The fringe projection system of the ATOS series is used for production quality assurance of small to medium-sized parts and excels by its high precision for fine details. ATOS Capsule is utilized, for example, for first article inspection of gears, turbine blades and wheels as well as medical parts.

ATOS Capsule in Use

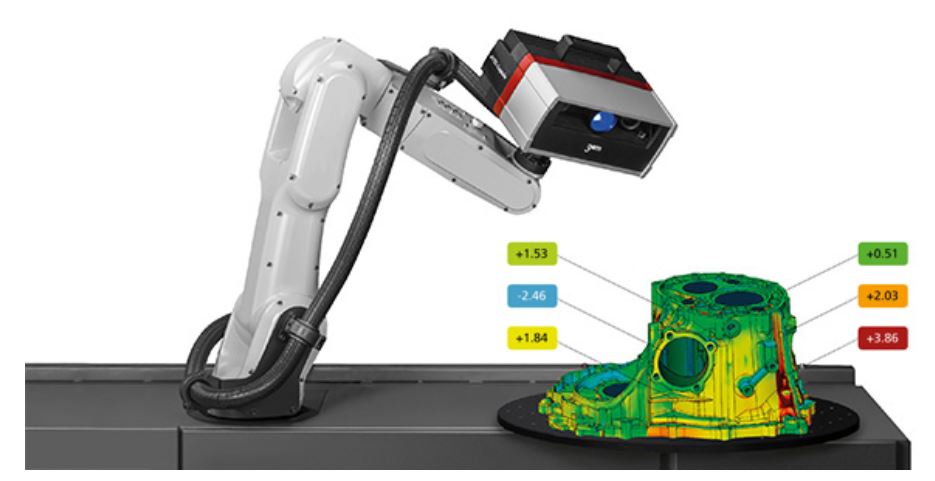

In the standardized measuring machine ATOS ScanBox, the ATOS Capsule is used for fully automated measuring and inspection of contoured parts. Used in the ATOS ScanBox of series 4, the ATOS Capsule serves as a mobile and therefore flexible measuring system for small parts. In the ATOS ScanBox models of series 5 and 6, the ATOS Capsule can be extended with a Plus Box photogrammetry add-on. Thus, bigger components or several parts can be measured simultaneously.

ATOS Capsule Technology

Due to its housing design, the ATOS Capsule provides process stability for automated applications. Made of aluminum investment casting, the precisely manufactured unibody housing ensures maximum stiffness and precise measuring results for industrial use. Optics and electronics are protected against dust and splashing water.

Triple Scan Technology

Together with both cameras, the projection unit operates according to the triple scan principle. During the measurement, precise fringe patterns are projected onto the surface of the object and are recorded by two cameras, based on the stereo camera principle. This automatic principle offers advantages in measuring reflective surfaces or objects with complex indentations.

Blue Light Technology

The projection unit of the ATOS Capsule system is based on Blue Light Technology. Since the sensor works with narrow-band blue light, interfering ambient light can be filtered during image acquisition. Due to its powerful light source, short measuring times can be achieved.

Self-Monitoring System

The sensor recognizes changing ambient conditions during operation and is able to compensate these changes. To do so, the software of the sensor is continuously monitoring the calibration status, the transformation accuracy, environmental changes and part movements to ensure the quality of the measuring data.

ATOS Plus

In GOM’s automated measuring machines, ATOS sensors can be operated together with the Plus Box. This is a photogrammetric add-on sensor, which is directly mounted onto the ATOS system. It allows for fully automated measuring of reference point markers with a deviation of 3 μm to 15 μm. These reference point markers create a 3D volume, in which the detailed individual measurements of the ATOS Capsule are transformed automatically. Thus, the overall accuracy of the overarching photogrammetric measurement is achieved.

Virtual Measuring Room

Virtual Measuring Room

The virtual measuring room (VMR) is the central control station and measurement planning software for all elements of the ATOS measuring cells. It offers the functional representation of a real measurement environment in a virtual simulation. Due to the VMR, the user can work with the system without the requirement for specific robot programming skills. All robot movements are simulated and checked for safety before being performed in the virtual measuring room.

Parametric Inspection

The ATOS Professional evaluation software provides all necessary tools for a comprehensive analysis of parts and components. Using parametric inspection, all actions and evaluation steps are completely traceable and interlinked. Thus, changes and modifications are possible at any time.