ABB YuMi Datasheet

October 10, 2018, Queen Sirikit National Convention Center, Bangkok, Thailand

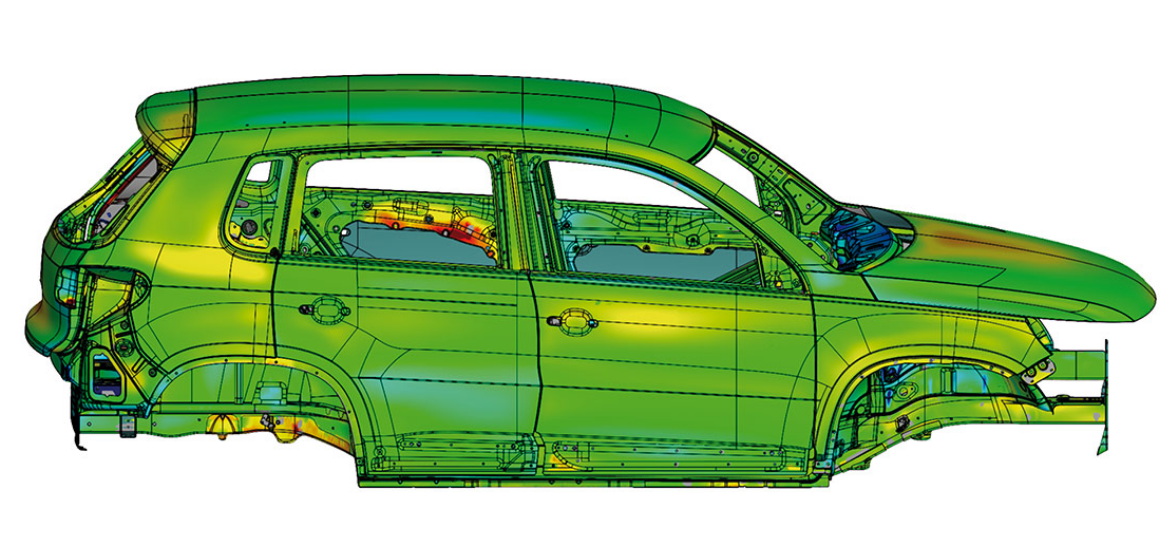

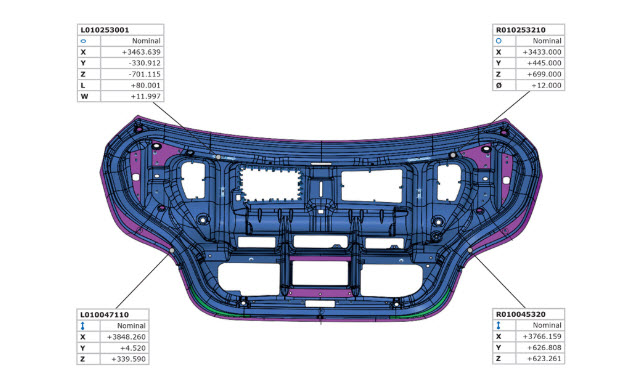

The GOM CT enables the inspection of complex parts based on volumes. All surfaces – even internal structures – can, for example, be used for shape and dimension analyses or nominal-actual comparisons.

Dimensions

H. 2130 mm

W. 2200 mm

D. 1230 mm

Weight

4800 kg

Connection

400 V / 3-phase / 16 A

The GOM CT enables the inspection of complex parts based on volumes. All surfaces – even internal

structures – can, for example, be used for shape and dimension analyses or nominal-actual comparisons.

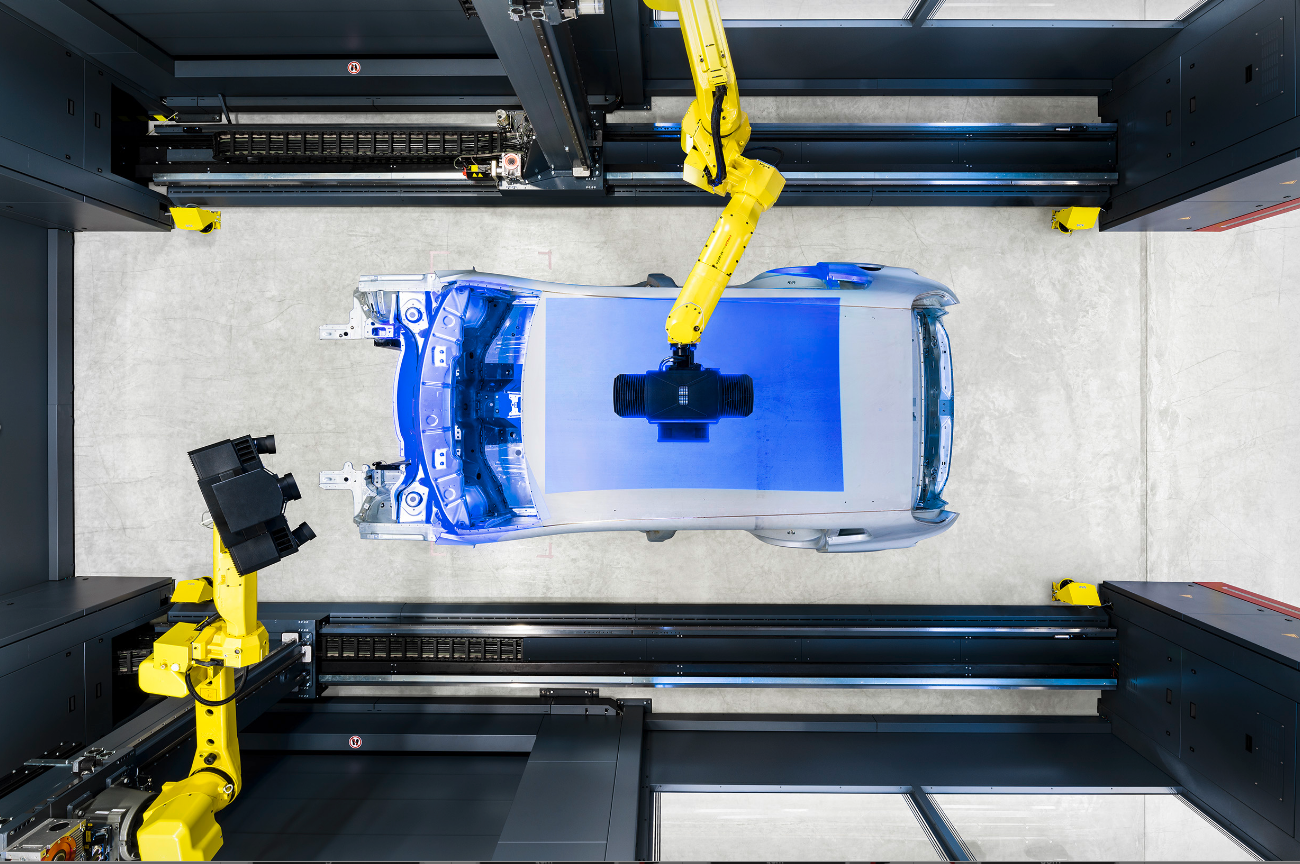

With its powerful light source, ATOS 5X enables the use of large measuring volumes for maximum speed in

automated applications. In combination with the ATOS ScanBox series, ATOS 5X is a high-end scanning

system for tool, press and body shops.

ATOS 5X uses the integrated Laser Light Compressor to generate ultra-bright light. This allows for

measuring areas of up to 1000 mm and at the same time extremely short exposure times. Acquisition

times of 0.2 seconds are reached.

The automated measurement of a complete car body both outside and inside typically takes 30 minutes with ATOS 5X – including the precise coverage of complex geometries. The system enables the highest possible throughput, with the main application areas in Meisterbock and Cubing, inspection of complete vehicles and quality control in body manufacturing.

ATOS 5

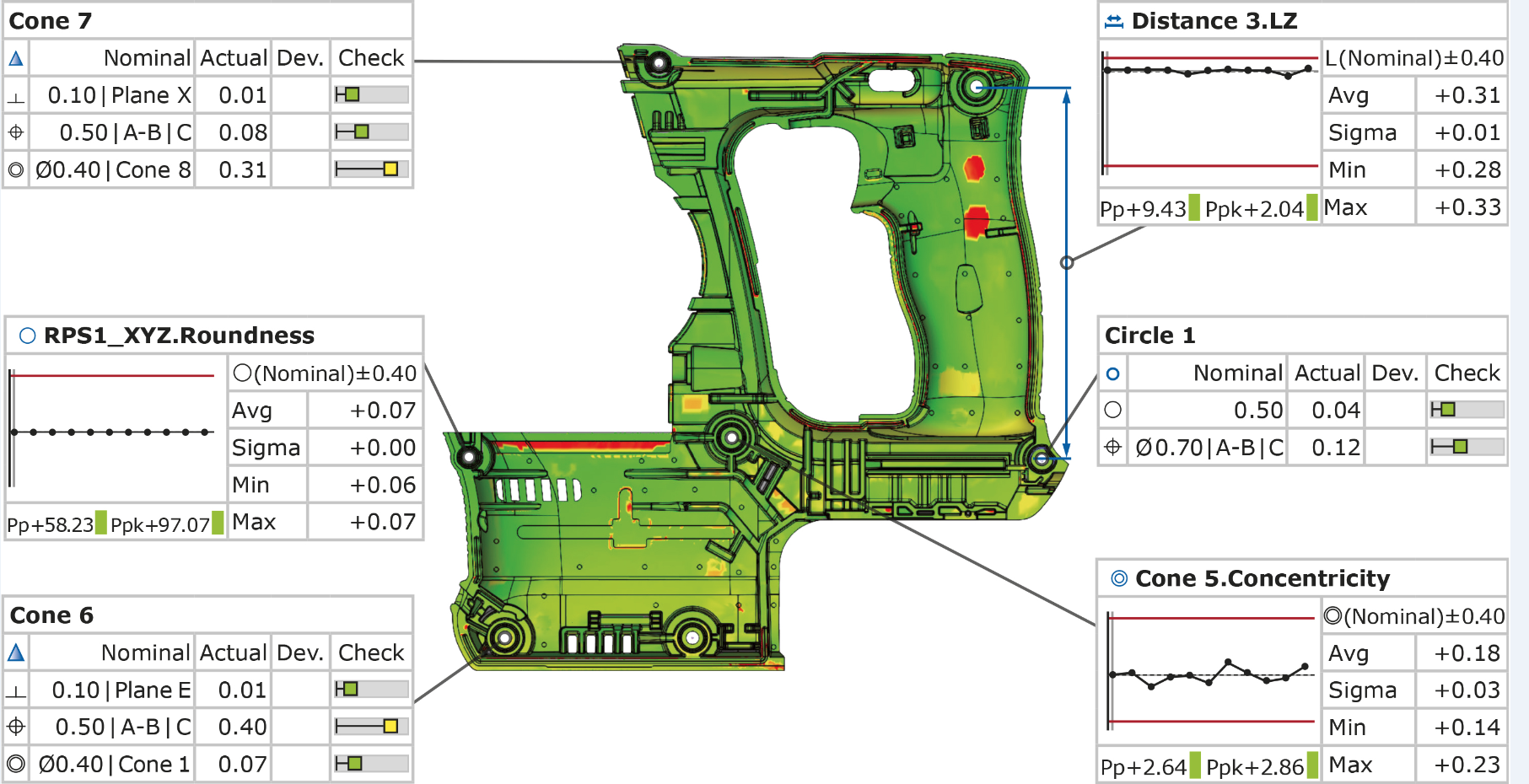

ATOS 5Developed for industrial use, ATOS 5 delivers high-precision data in a short measuring time even under harsh conditions. The full-field 3D measuring data allows comprehensive process and quality control, visualizing hidden errors and thus speeding up production processes.

With its powerful light source, ATOS 5 delivers high-precision data for a diverse range of manual and automated applications: from tools and molds to plastic and metal parts. The GOM data quality is particularly evident in the detail sharpness of the 3D models, for example, in the precise display of smallest details, rib structures, narrow radii or hemmed edges.

GOM offers expert classroom courses targeted for mastering challenges in specific industries. Procedures, workflows, tips and tricks are combined with detailed technical background knowledge and extensive practical exercises with hardware and software.

The trainers of the expert courses are experts with vast theoretical knowledge and many years of experience in the respective fields. This combination ensures that you get professional answers also to questions beyond the content of the training.

Basic level and advanced level skills on operating the GOM systems and software are recommended for these training courses. Furthermore, watching the training webinars and videos on specific topics might help to master the training courses successfully.

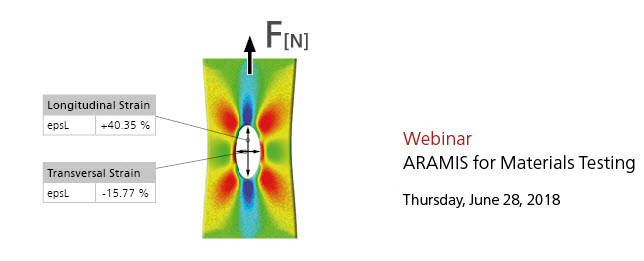

Whether you are a CAE engineer working with material models for numerical simulations or a test engineer characterizing the mechanical properties of materials, you know that working with accurate material parameters is crucial for taking the right decisions during the design phase of your product to ensure the best performance over the entire life cycle.

Digital image correlation is a versatile and powerful analysis technique for measuring 3D data for deformation analysis of both materials and components.

On June 28, 2018, at 9:00 a.m. CEST, 1:00 p.m. CEST and 5:00 p.m. CEST, GOM invites you to the webinar “ARAMIS for Materials Testing” held in English and German to learn how ARAMIS will enhance your testing capabilities in:

The webinar will take about 30 minutes.