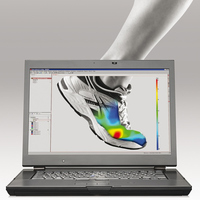

GOM provides a complete solution with the ARAMIS for measuring, evaluation and reporting.

Please find more information about the ARAMIS system in the ARAMIS metrology system page.

GOM completely develops the ARAMIS hardware and software in house. The software is designed to run the sensor and controller, to process all measurements, to automatically compute result data and to perform post-processing.

ARAMIS is an industrial grade solution providing all necessary functionalities even for complex research tasks.

ARAMIS is integrated in standard process chains through versatile import and export capabilities. Material parameters, testing device outputs and data logs are imported and used for further calculation of characteristic values.

ARAMIS is integrated in standard process chains through versatile import and export capabilities. Material parameters, testing device outputs and data logs are imported and used for further calculation of characteristic values.

CAD data can be used for transformations and deviation calculations.

- Native: Catia v4/v5, UG, ProE

- General: IGES, STL, VDA, STEP

To close the process loop, all result data are exported in standard or free definable formats.

All workflows are available for automated use with a record and play procedure. New analysis models can easily be implemented by the operator and added to the standard evaluation as ARAMIS offers a scripting interface.

All built-in features enable ARAMIS to:

- Integrate in existing testing and measuring workflows

- Link with existing evaluation strategies

- Adapt to any measuring and evaluation task

Features

Data Acquisition

- Comfortable interface for different camera models

- Flexible triggering of image aquisition (manual, time sequence, TTL signal or load signal from the experiment, …)

- Import of images from external cameras

- Integrated data logger and trigger box

- Multiple measurement units can be triggered to grab images simultaneously or in sequence

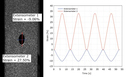

- ARAMIS Real Time Sensor, Live tracking of several facets and ellipses in 3D without image saving, 3D coordinates of several points are computed in real time on snapped images

Computation

- Fast correlation computation over all loading stages

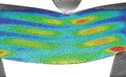

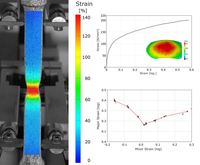

- Automatic calculation of the 3D surface coordinates, 3D displacements (cartesian and radial coordinates) and the plane strain tensor

- Calculation of stresses if the corresponding material data are known

Registration

- Elimination of the rigid body movement

- Registration of the captured data into predefined coordinate systems or into predefined geometrical elements (primitives)

- Registration to CAD or STL

- Combination of multiple measurement areas

STL and CAD Data Import:

- STL data and CAD data, (CATIA V4/V5, Pro/Engineer, IGES, STEP, VDA, …)

- Calculation of the deviation from measured data to reference data (points, distances)

Primitives

- Primitives (spheres, cylinders, cones, planes, lines, …) can be generated from mesh data (certified by PTB and NIST)

- Full featured geometry based analysis (Point-Point distance, Point-Plane distance, Angles, …)

Section Data

- Definition of sections on 3D measurement data

- Visualization of section data in diagrams

FEA Comparison

- Native import of FEA data-sets (ABAQUS, LS-DYNA, PAM-STAMP, AutoForm and ASCII)

- Full-field comparison of geometry, deformation, displacements and strain values Calculation and comparison of major and minor strain, thickness reduction, 3D shape/geometry, X, Y, Z displacements, …

- Export of data-sets and results (surface data, ASCII, sections, diagrams, images, reports, …)

Documentation and Reporting

- Result data overlay on captured images

- Result visualization of strain images, graphical diagrams, analog signals, … in reports

- Dynamically linked reports for live updating of results Variable and adjustable templates for reports

- Result visualization in z-axis for easy comparison to FE-computation

Statistic functionality and exports - Export of results (ASCII, movies, images)

Forming Limit Curve (FLC)

- Determination of forming limit curve based upon ISO 12004

- Time or section based evaluation

- Evaluation of complete measurement series

Automation

- Macro functionality for easy recording, editing and launching of repetitive steps in image acquisition, post processing and data evaluation

Help

- Automated parameter suggestions for all important functions

- Online Help

Software Administration

- All software features completely controllable with seperate administration licence

- Adapt the software to company-specific workflows

- Disable specific system menus and functions

- Integrate user-defined scripts into menus

- Lock system templates so that only company-specific templates are available

- Block creation or editing of templates, scripts or automation protocols

Hardware

- Direct interface with testing machines

- Easily transportable systems